Blog

Share this

What Are Raw Materials of Olive Oil Bottle Cap

Nov 11, 2025 17:55:03

Olive oil is rich in unsaturated fatty acids and vitamin E. However, prolonged exposure to air, light, or high temperatures can easily lead to oxidation, resulting in a deterioration in flavor (such as developing a rancid taste) and nutrient loss.

Furthermore, its viscosity is higher than that of regular cooking oils, and if the cap doesn't seal well, it can easily leak or drip. Therefore, choosing olive oil bottle caps essentially revolves around three core requirements: "sealing," "anti-oxidation," and "ease of use."

Main Structures

1. Screw Cap

The most basic and widespread choice, offering the best value. The screw cap is probably the most familiar structure, similar to the caps on soy sauce or vinegar bottles, where the threads inside the cap engage with the bottle opening. The advantages of this structure are obvious: stable sealing, as tightening it essentially prevents air from entering; low cost, suitable for inexpensive olive oil or large bottles (such as 5L family bottles); and easy to use, even for the elderly and children.

However, even regular screw caps have undergone a minor upgrade – many brands add a "sealing gasket" (usually made of food-grade silicone or foam) to the inside of the cap. When tightened, the gasket fits snugly against the bottle opening, further reducing air intake.

Some high-end brands are even designed as "pilfer proof screw caps," requiring the tamper-evident ring on the top of the cap to be broken upon first use. This ensures a tight seal even when unopened and allows consumers to verify if the product has been tampered with.

2. Press-down Flip Caps

If you frequently use olive oil for stir-frying or salad dressing, press-down flip caps might feel convenient. These caps typically consist of two parts: a base fixed to the bottle opening and a flip-up cap body. Additionally, press-down flip caps often feature a small oil outlet to control the amount of oil dispensed, preventing over-dispensing – a practical detail.

The core advantage of press-down flip caps is that they are screw-on, eliminating the need to strain the cap each time. They can be operated with one hand, making them especially suitable for use when your hands are wet or oily. However, it's important to note that the sealing of this type of structure relies primarily on the silicone sealing ring between the cap and the base. Therefore, when purchasing, check that the sealing ring is intact and has sufficient elasticity.

3. Dropper/Pump Head

For small bottles of extra virgin olive oil (e.g., 100ml, 250ml), many brands opt for dropper or pump head designs. This design prioritizes "precise usage." A dropper cap is like a laboratory dropper; a gentle squeeze dispenses drops of olive oil. A pump head is similar to a hand sanitizer pump, dispensing one drop at a time, with a relatively fixed amount (usually 5ml-10ml).

The advantage of this design is precise dispensing, making it suitable for use in salads and as a garnish (e.g., drizzled over steak or pizza), avoiding waste. Additionally, the dropper or pump design minimizes the olive oil's contact with air. However, this design is more expensive and typically only used for high-end olive oils. It's also relatively difficult to clean and not suitable for repeated use.

Material Selection

1. Food-Grade Plastic

Plastic is the most common material for olive oil bottle caps, specifically "food-grade plastic" (such as PP polypropylene and PE polyethylene). This material has many advantages: lightweight, drop-resistant, grease-resistant. More importantly, it's low-cost, suitable for mass production.

However, when choosing plastic bottle caps, pay attention to two points: firstly, check if the material is labeled "food-grade" to avoid buying inferior plastic (inferior plastic may release harmful substances when in contact with grease or high temperatures); secondly, pay attention to the cap's "aging resistance"—some cheap plastic caps become brittle and crack over time, affecting the seal, so choose plastic caps that are sturdy and have a smooth surface.

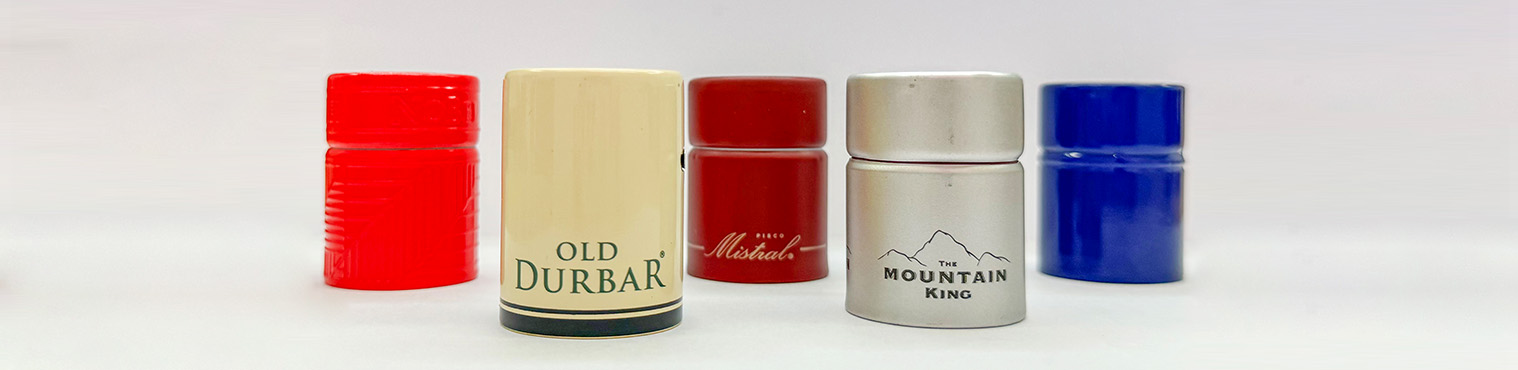

2. Metal

Metal bottle screw caps (usually aluminum alloy or tinplate) are generally found on mid-to-high-end olive oils. Their biggest feature is their superior quality—the metallic sheen enhances the overall grade of the bottle, perfectly matching the positioning of high-end olive oil.

In addition, metal has better sealing and anti-aging properties than plastic, and it better isolates air and light (some metal caps have an inner wall to further enhance light protection), thus extending the shelf life of olive oil.

Furthermore, metal caps are more expensive than plastic ones, so the olive oil packaged with them is usually more expensive. It's also important to note that the inside of the metal cap must have a food-grade coating or gasket to prevent direct contact between the metal and the olive oil, thus avoiding chemical reactions.

Original source: https://www.alubottlecaps.com/a/what-are-raw-materials-of-olive-oil-bottle-cap.html

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible