Blog

Share this

What Are Requirements Of The Alcohol Bottle Cap

May 15, 2025 10:25:18

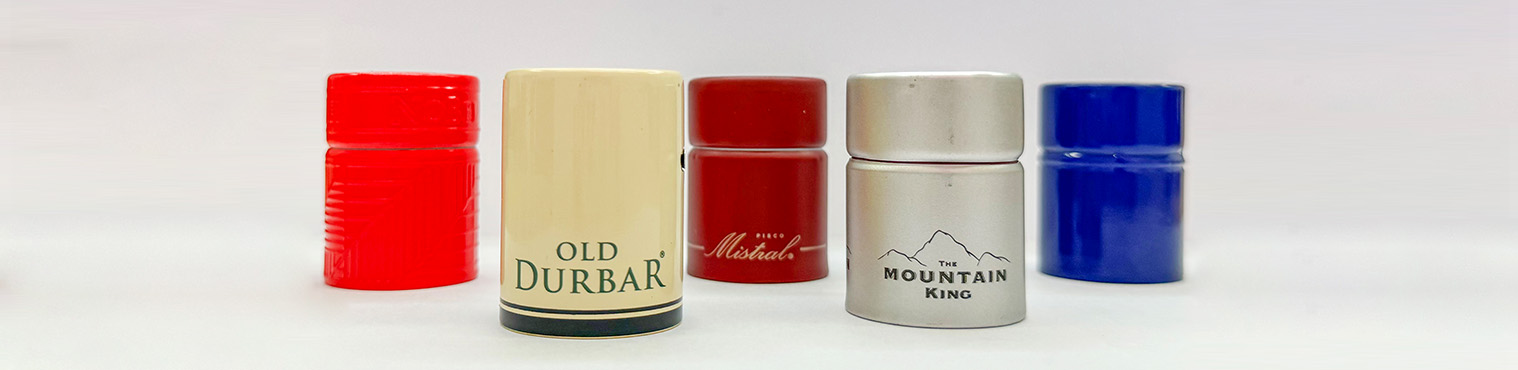

In the world of wine packaging, the small alcohol bottle cap is the first line of defense to protect the quality of the wine. Especially for spirits with high alcohol content and complex ingredients, the design and material selection of the bottle cap directly affect the flavor retention, safety and market value of the wine.

The core requirements of wine bottle caps

1. Extreme sealing

No matter what kind of wine, the core mission of the bottle cap is to build a closed space. Ordinary liquor needs to prevent ethanol from volatilizing and causing "wine leakage", wine needs to isolate oxygen to prevent tannin oxidation, and beer needs to prevent carbon dioxide from escaping. High-quality bottle caps must pass triple sealing tests: static sealing (storage at room temperature), dynamic sealing (transportation bumps), and temperature difference sealing (environmental changes of 5℃-40℃), ensuring that the sealing performance remains stable within the temperature range of -20℃ to 60℃.

2. Material safety

The material of the bottle cap must pass the migration test to prevent the precipitation of harmful substances such as plasticizers and heavy metals. Among the common materials, food-grade PE gaskets have become the mainstream due to their low temperature resistance and anti-aging advantages, while aluminum outer caps are widely used due to their good thermal conductivity and ductility.

3. Opening experience

An ideal bottle cap should have the characteristics of "easy to open, difficult to open by mistake". The number of teeth on the beer bottle cap is fixed at 21, which is the golden balance point between the opening torque and the sealing performance; the screw cap of the wine is designed with a 2.5-turn rotation stroke, allowing consumers to operate it with one hand. High-end spirits bottle caps often add anti-misopening structures, such as a double locking design that requires pressing and rotating to prevent children from accidentally ingesting.

4. Anti-counterfeiting function

Traditional anti-counterfeiting relies on physical means such as laser engraving and embossing coding, while high-end spirits have entered the era of intelligent anti-counterfeiting.

Special technical standards for spirit bottle caps

When the alcohol content of the liquor exceeds 40% vol, ordinary plastic caps will face the risk of "alcohol swelling" - ethanol molecules penetrate the material to cause expansion and deformation. Experimental data show that when 52% vol liquor is stored in ordinary PET caps for 6 months, the amount of methanol migration will exceed the standard by 3 times. Therefore, the combination of aluminum body + polytetrafluoroethylene (PTFE) gasket is preferred by liquor bottle covers.

Original source: https://www.alubottlecaps.com/a/what-are-requirements-of-the-alcohol-bottle-cap.html

Previous : What are Types of Bottle Cap Sodas

Next : What Are Glass Bottle Caps

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible