Blog

Share this

Why Is The Threaded Aluminum Cap So Popular

May 22, 2025 10:45:28

In the field of packaging, small bottle caps often play a vital role. With its unique performance advantages, the threaded aluminum cap is emerging in many industries such as food, medicine, and daily chemicals.

Core performance advantages of threaded aluminum caps

1. Excellent sealing and protection performance

The threaded aluminum caps manufactured by high-precision cold stamping technology have a thread accuracy of up to 0.02mm, and can form a tight mechanical bite with the bottle body thread. By optimizing the sealing gasket material (nitrile rubber, silicone, etc.), stable sealing can be achieved within the temperature range of -40℃ to 120℃, effectively blocking oxygen, water vapor and odor, and are particularly suitable for food (such as milk powder, health products) and pharmaceutical packaging that are sensitive to the storage environment.

2. Lightweight and high-strength material properties

The weight of the aluminum bottle cap is only 60% of that of similar plastic caps, but it can withstand an opening torque of more than 50N and an internal pressure test of 80kPa. The corrosion resistance of aluminum metal itself is better than that of tinplate, and it is not easy to rust in high humidity and high salt environments. This feature makes it excellent in packaging scenarios such as canned seafood and condiments. The surface can be formed into a protective film with a thickness of 0.3-1.5μm through processes such as anodizing and electrophoretic painting, further improving weather resistance.

3. Convenient use experience

The humanized anti-slip pattern design (common knurling and mesh technology) controls the opening torque within a reasonable range of 8-15N・m, which not only ensures that it is not easy for children to open (in line with the US ASTM F963 standard), but also facilitates one-handed operation for adults. The tear-off ring structure equipped with some pharmaceutical aluminum caps can be opened once and leave traces of damage, meeting the anti-counterfeiting needs of pharmaceutical packaging.

4. Sustainable advantages of green environmental protection

Aluminum has the characteristics of infinite recycling and regeneration, with a recycling rate of more than 95%, and the energy consumption of the recycling process is only 5% of that of primary aluminum. Compared with the common PP and PE materials of plastic caps, the VOC emissions of aluminum caps during production are reduced by 40%, and they do not contain harmful substances such as bisphenol A, which meets the EU EC 1935/2004 food contact material safety standards, becoming the preferred solution for green packaging upgrades.

Application practice in multiple scenarios

1. Food and beverage packaging

In the field of bottled water and functional beverages, 28mm diameter threaded aluminum caps have gradually replaced traditional plastic caps with their good sealing and lightweight advantages, and are especially suitable for high-end water brands to enhance product quality. In canned food, the combination of aluminum caps and tinplate cans achieves full metal packaging, which can still maintain sealing integrity during the 121℃ high-temperature sterilization process and extend the shelf life of food. Baking raw material packaging (such as milk powder and coffee powder) uses aluminum caps with desiccant design to control the humidity in the package below 3%.

2. Medical and health care packaging

Medical aluminum caps must meet international standards such as USP <661> and EP 1.3.2, and their sealing performance is directly related to drug safety. In oral liquid bottles and vials, aluminum caps are combined with rubber stoppers to form a double seal, and can still maintain a vacuum state after freeze-drying. Aluminum caps commonly used in health care product packaging integrate anti-counterfeiting code printing technology. Consumers can verify the authenticity of the product by scanning the QR code inside the cap. At the same time, the metallic texture of the aluminum material enhances the brand's high-end image.

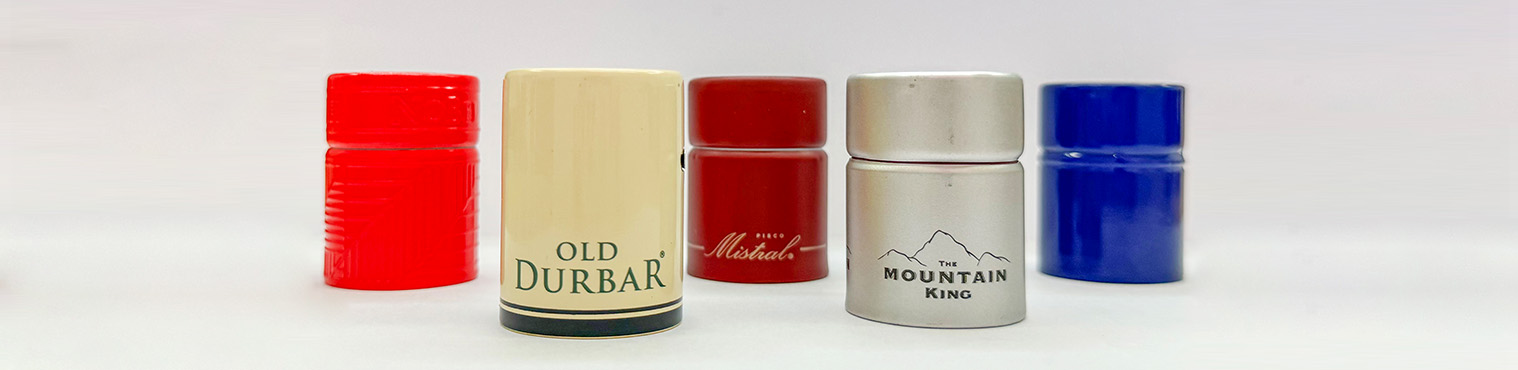

3. Daily cosmetic packaging

In the field of skin care products, aluminum caps are often paired with glass and acrylic bottles for high-end product packaging such as essences and creams. The surface treatment process can achieve anodizing coloring (supports Pantone color card customization), electroplating brushing, hot stamping and other effects to enhance the visual impact of the product. The aluminum valve cover used in aerosol packaging can withstand an internal pressure of 1.2MPa to ensure the stable operation of the spray system. It is widely used in products such as sunscreen spray and styling hair spray.

4. Wine packaging

In the field of wine and spirits, aluminum pp caps replace traditional heat shrink caps and are customized through laser engraving, embossing printing and other processes. The threaded structure is used with bottle stoppers to reduce the risk of cork contamination and facilitate secondary sealing for consumers. The screw top aluminum bottles of craft beer is treated with a special coating, which can effectively block the damage of ultraviolet rays to hops and maintain the stability of flavor.

Original source: https://www.alubottlecaps.com/a/why-is-the-threaded-aluminum-cap-so-popular.html

Previous : What Are Glass Bottle Caps

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible