Blog

Share this

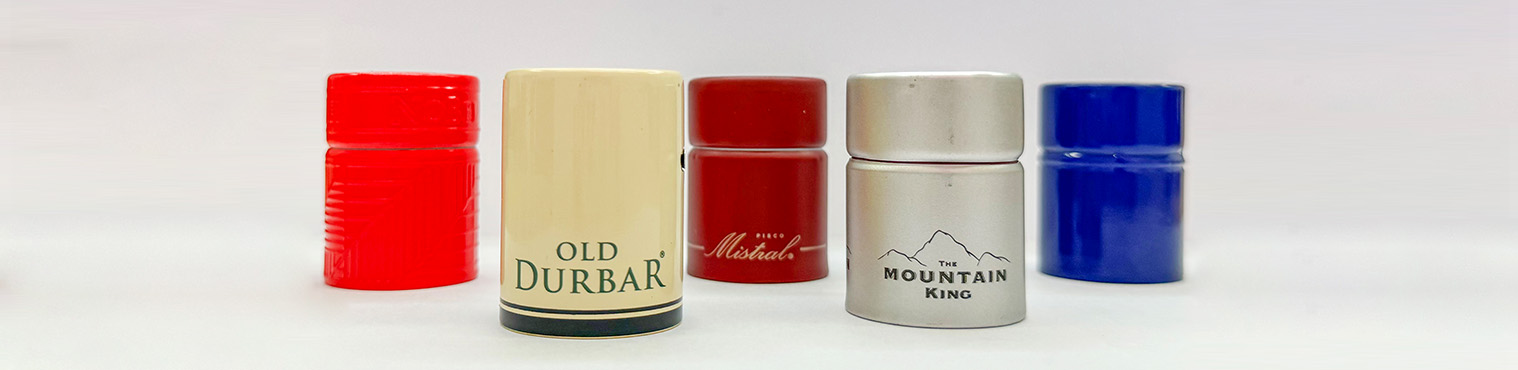

China Aluminum Plastic Trim Caps and Plastic Twist Cap

Jun 12, 2025 09:54:47

The aluminum plastic trim cap is a composite bottle cap that organically combines aluminum materials with plastic inner parts. The outer layer uses a 0.2-0.3mm thick aluminum alloy sheet, which is formed into a three-dimensional shape through a stamping process, and the inner layer is a sealing inner pad made of high-density polyethylene (HDPE) or polypropylene (PP). This double-layer structure of "aluminum outside and plastic inside" not only retains the texture and luster of the metal, but also gives full play to the flexible sealing characteristics of the plastic.

Core characteristics and process highlights

Decorative advantages: The aluminum shell can be realized with a variety of processes such as relief, hollowing, hot stamping, and color printing. It is commonly seen on the bottle caps of high-end liquors, such as Wuliangye's "crystal cap" with a concave and convex ribbed design and a brand LOGO relief, becoming a visual focus. Surface treatment technology can also achieve matte, mirror and other texture effects to meet the personalized needs of luxury packaging.

Sealing performance: The inner plastic pad is bonded to the aluminum shell using an in-mold injection molding process to form a tight sealing structure. Some high-end bottle caps also have built-in anti-counterfeiting rings or tear strips, which produce destructive marks when opened and have anti-counterfeiting functions.

Material characteristics: Aluminum alloy has good ductility and corrosion resistance, and is not easy to rust even if stored for a long time, while the plastic inner pad can adapt to the temperature range of -40℃ to 120℃, meeting the storage requirements of different products such as wine and health products.

Application scenarios

Aluminum plastic trim cap are mainly used in packaging scenarios such as mid-to-high-end wines (white wine, wine), tonics (bird's nest, ginseng slice gift boxes), and cosmetics (essential oil bottles, cream jars). For example, Moutai's aluminum-plastic cap uses a classic red matte shell with a hot-stamped gear pattern, which not only highlights the brand's nobleness, but also enhances the product's credibility through a built-in anti-counterfeiting chip.

The biggest highlight of the plastic twist off cap is its unique anti-theft design. The twist-off ring set on the cap is connected to the cap body, forming a complete sealing structure when it is not opened. When consumers open the package for the first time, they must twist off the twist-off ring with force to open the cap. This design not only effectively prevents the product from being opened and contaminated at will during transportation and storage, but also allows consumers to intuitively judge whether the product is used for the first time, greatly enhancing the safety and credibility of the product.

In addition to the anti-theft function, plastic twist-off caps also excel in practicality and convenience. The material usually has good toughness and strength, and can adapt to different production processes and packaging requirements.

Moreover, the opening method of the twist-off cap is simple and easy to understand. Consumers can open it with a light twist without the help of additional tools, and the user experience is friendly.

From food and beverage to personal care, from medical care to household cleaning, plastic twist-off caps have become the first choice for packaging in many industries due to their excellent performance.

Original source: https://www.alubottlecaps.com/a/china-aluminum-plastic-trim-caps-and-plastic-twist-cap.html

Previous : Aluminium ROPP Caps and PP Caps

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible