Blog

Share this

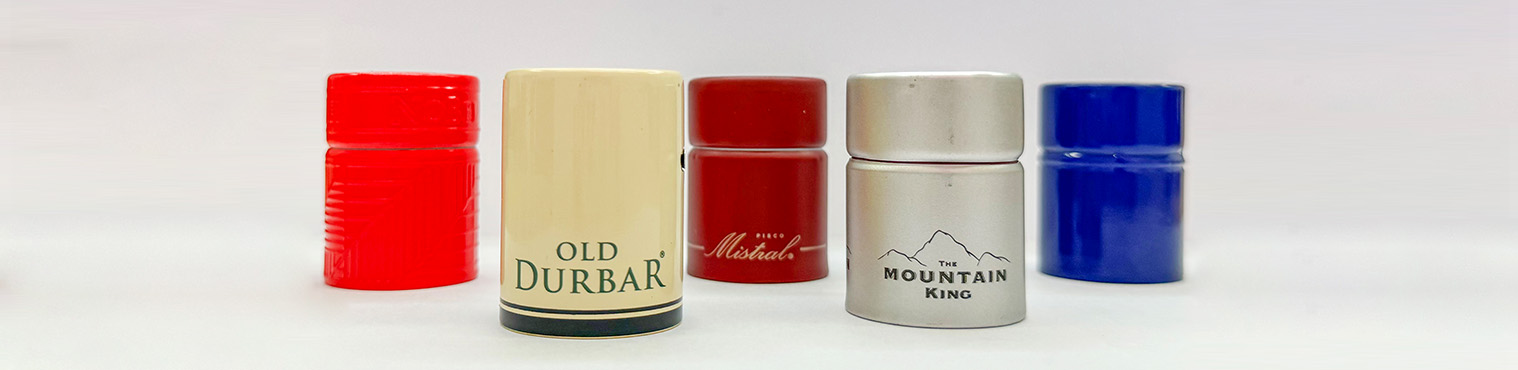

Cast Aluminium Caps VS Aluminium Seal Caps

Aug 07, 2025 11:47:28

Cast aluminum caps are made primarily from aluminum through a casting process. Aluminum, a lightweight and high-performance metal, offers excellent plasticity, thermal conductivity, and corrosion resistance, which underpins the excellent performance of cast aluminum covers. The casting process involves heating aluminum to a molten state, pouring it into a prefabricated mold, and allowing it to cool and solidify into a custom-shaped cover. This process allows for precise shaping of complex structures to meet the needs of diverse applications.

Cast aluminum covers offer outstanding performance characteristics. First, their light weight is a major advantage. Compared to covers made of materials like cast iron, cast aluminum covers are significantly lighter, making them easier to transport and install, while also reducing the weight of associated equipment and saving energy.

Secondly, they are highly corrosion-resistant. Aluminum forms a dense oxide film in the air, effectively preventing further corrosion of the internal aluminum. This allows cast aluminum caps to maintain excellent performance even in humid and corrosive environments, extending their service life. Furthermore, cast aluminum covers offer excellent thermal conductivity, allowing them to quickly dissipate internal heat in equipment requiring heat dissipation, ensuring proper operation.

Cast aluminum covers are used in nearly every industry. In the automotive industry, they are often used as end covers for components like engines and transmissions, sealing and protecting internal parts. In mechanical equipment manufacturing, cast aluminum covers are also used on various machine tools, pumps, and valves, providing dust and water protection and securing components. In household appliances, compressor end covers for air conditioners and refrigerators, as well as some oven covers, may also be made of cast aluminum, meeting performance requirements while embracing lightweight design.

The core advantage of the aluminium seal cap lies in its exceptional sealing capabilities. Aluminum's inherent ductility and plasticity allow it to fit tightly to the container's opening during processing, forming a tight barrier that effectively blocks the intrusion of external factors such as air, moisture, and dust.

For the food industry, this means maximizing the shelf life of food and preventing oxidation and spoilage. In the pharmaceutical sector, it ensures that medications are protected from moisture and spoilage, ensuring the stability of their efficacy. In the cosmetics industry, high-quality aluminum closures prevent skincare products from oxidizing and losing their effectiveness due to exposure to air, ensuring they remain in optimal condition with every use.

Aluminum closures aren't one-size-fits-all; instead, they can be designed in a variety of ways to meet specific product needs. They come in a variety of styles, including flat-top, domed, and with pull tabs. Functionally, they can be fitted with gaskets for enhanced sealing or designed as easy-open versions for consumer convenience. This flexibility allows aluminum seal caps to adapt to a wide range of container sizes and usage scenarios. Whether it's a bottle stopper for oral liquids or a closure for an industrial storage tank, there's a suitable aluminum solution, fully demonstrating its wide applicability.

Original source: https://www.alubottlecaps.com/a/cast-aluminium-caps-vs-aluminium-seal-caps.html

Previous : What Are Uses of Aluminum Easy Peel Off End

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible