Blog

Share this

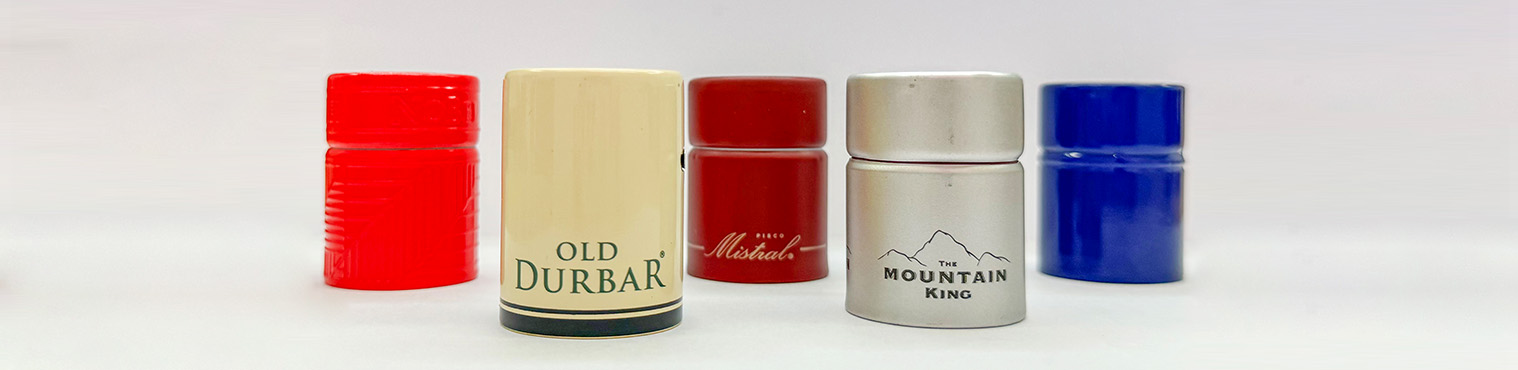

Custom Printed Aluminum Caps for Wholesale

Dec 31, 2025 11:22:38

In the packaging industry, aluminum bottle caps, with their superior texture, strong sealing properties, and environmentally friendly recyclability, have become the preferred packaging accessory for many categories, including wine, beverages, health products, and condiments.

Custom printed aluminum caps that perfectly match the product's style often requires meticulous customization. We have been deeply involved in the aluminum bottle cap customization field for many years and can respond to all kinds of customization needs.

Appearance Customization

1. Color Customization

We support full-range color customization. Whether it's basic gold, silver, black, gray, or white, or niche colors like Morandi colors or metallic gradients, we can precisely mix and match your needs. Using environmentally friendly coatings and high-temperature curing, the color is even and full, with strong adhesion, and is not easy to fade or scratch. It meets food contact safety standards while presenting a high-end visual effect, suitable for different product packaging styles.

2. Printing Process

For logo, text, and graphic printing needs, we offer a wide range of printing processes to ensure clear and exquisite printing results, combining aesthetics and durability. Optional processes include: screen printing, suitable for simple logos and text, with vibrant colors and moderate cost; heat transfer printing, capable of printing complex patterns with high fidelity and delicate details; hot stamping (gold/silver), using high-temperature embossing to create a metallic texture, enhancing the bottle cap's premium feel and suitable for high-end products; and UV printing, producing a three-dimensional effect, wear-resistant, scratch-resistant, environmentally friendly, and odorless, meeting the needs of various scenarios.

3. Logo Customization

As the core symbol of a brand, the logo can be precisely customized. Whether it's a flat or 3D logo, it can be achieved through printing, embossing, and debossing. We strictly control the logo's proportions, clarity, and placement to ensure that each customized bottle cap becomes a small carrier of brand communication.

Embossing/debossing gives the logo a strong three-dimensional feel and clear tactile texture, enhancing the bottle cap's quality and recognizability; flat printing accurately reproduces the logo's colors and details, making brand information immediately clear.

4. Texture Customization

Based on product positioning, we can customize various surface textures to create a differentiated experience. Optional textures include: frosted texture, with a delicate and soft touch, presenting a low-key and sophisticated style, suitable for high-end wines and health products; glossy texture, with a smooth and shiny surface, easy to clean, and visually simple and elegant; brushed texture, with a delicate texture created through a brushing process, combining metallic and fashionable qualities, suitable for beverages favored by young consumers; and also matte and sandblasted textures, which can be customized to ensure the feel and visual effect of the cap perfectly match the product's character.

Size Customization

Size accuracy is key to the fit between aluminum bottle caps and bottles. We can customize exclusive sizes according to your bottle specifications, while strictly controlling tolerances to ensure that every cap achieves a precise fit, improving sealing and user experience.

1. Core Dimensions

We support full-dimensional customization of core dimensions, including thread specifications, diameter, cap height, outer diameter, and inner diameter. Thread specifications can adapt to different bottle designs, whether it's standard threads, tamper-evident threads, or custom-made threads, all can be precisely matched.

Diameters range from standard 18mm, 20mm, and 28mm to custom sizes, all can be produced to order. Cap height and inner/outer diameters can be flexibly adjusted based on bottle proportions, product capacity, and other factors to ensure a harmonious fit between the cap and bottle, maintaining both product appearance and sealing performance.

2. Tolerance Control

We possess advanced production equipment and a rigorous quality control system, meticulously controlling the tolerances of every dimension. Standard dimensional tolerances are controlled within ±0.05mm, while special sizes can be further optimized to effectively prevent issues such as loose caps and leakage due to dimensional deviations. Each batch of customized products undergoes sampling inspection to ensure dimensional accuracy meets standards and guarantees a perfect fit with the bottle.

Functional Customization

Beyond appearance and dimensions, we prioritize the functional adaptability of our aluminum bottle caps. Customization of gasket materials and compatibility allows us to meet the storage and usage needs of different products.

1. Custom Compatibility

We can customize aluminum bottle caps to better suit your product type (e.g., wine, beverages, health supplements, condiments, etc.) and bottle material (glass, plastic, etc.). We optimize the internal design of the cap for different bottle neck structures, ensuring easy opening, excellent sealing, and preventing wear and tear on the bottle. Precise fit is available for both standard and irregular bottle shapes, providing a customized packaging solution for your product.

2. Custom Gasket Material

As a core component of the aluminum bottle cap's sealing performance, we support customization of various gasket materials to adapt to the storage needs of different products and ensure product quality.

Optional gasket materials include: food-grade silicone gaskets, which are resistant to high and low temperatures, have strong sealing properties, and are odorless, suitable for alcoholic beverages, soft drinks, and other food products; EVA gaskets, which are elastic, shockproof, leak-proof, and moderately priced, suitable for health supplements, condiments, etc.; PE gaskets, which are highly corrosion-resistant and suitable for various liquid products; and aluminum foil gaskets, which combine sealing and anti-counterfeiting functions, suitable for high-end products, and can effectively prevent product deterioration and leakage.

Customization Process

To provide you with a more convenient customization experience, we have established a standardized customization process: Needs Communication (clarifying your customization needs and product parameters) → Solution Design (providing design drawings and sample renderings) → Sample Production (quickly producing samples for your confirmation) → Mass Production (efficient mass production after sample confirmation, with strict quality control) → Logistics and Delivery (selecting delivery methods as needed to ensure timely product delivery)

A professional team will follow up throughout the process, providing timely progress feedback, allowing you to easily and effortlessly own your own custom aluminum bottle caps. Welcome to inquire wholesale aluminum caps price from us directly.

Original source: https://www.alubottlecaps.com/a/custom-printed-aluminum-caps-for-wholesale.html

Previous : Which Is Better for Wine Bottle: Plastic or Metal Screw Caps

Next : Already the first

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible