Blog

Share this

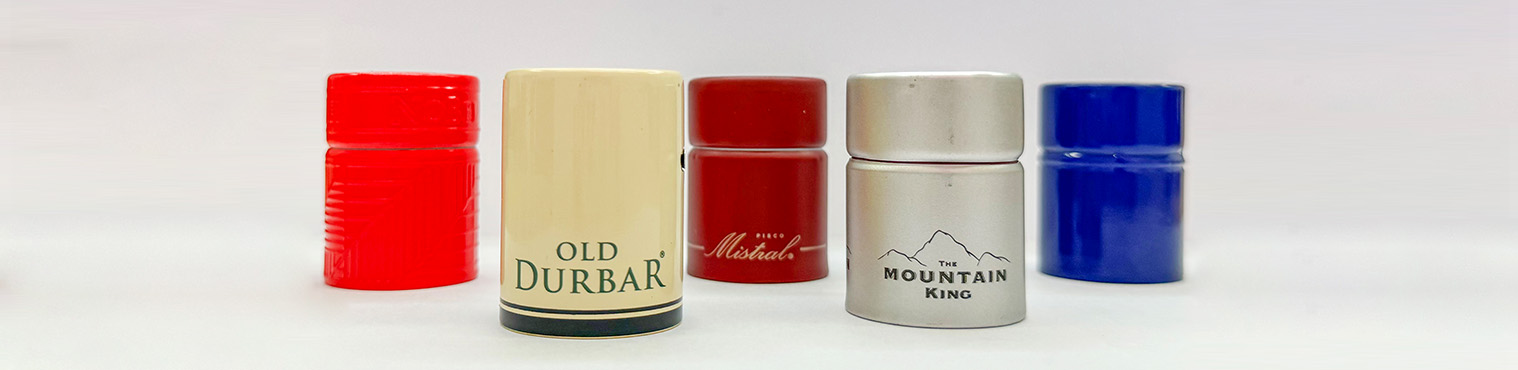

What Are Requirements of Water Bottle Caps

Jun 25, 2025 10:56:57

When discussing water bottle caps, we must first understand the water in the bottle. Common bottled water includes soda water, mineral water, purified water, mineral water, etc., each of which has its own characteristics.

Mineral water generally comes from unpolluted water sources deep underground, and has undergone a long stratum cycle, rich in minerals such as potassium, zinc, and metasilicic acid. Purified water is water without impurities, which is treated by electrodialysis, ion exchange and other technologies.

Mineral water uses purified water as raw water and adds mineral elements such as potassium and zinc. Soda water contains sodium bicarbonate and is weakly alkaline. Some soda water is naturally formed, while others are made by artificially adding carbon dioxide. Different types of bottled water also have different cap designs.

The primary function of the mineral water bottle cap is to ensure sealing, prevent liquid leakage and external contaminants from entering. It is generally composed of threads, sealing rings, and side sealing rings.

When tightened, the sealing ring fits the inside of the bottle mouth, the side sealing ring fits the outer edge of the bottle mouth, and the inner thread cooperates with the outer thread of the bottle mouth to generate friction to fix the bottle cap. The tight sealing design well maintains the quality of mineral water.

The caps of purified water and mineral water bottles also focus on sealing, because these two types of water are easily contaminated. At the same time, in order to attract consumers, some brands will make marketing designs on the bottle caps, such as printing QR codes inside to carry out prize-giving activities, which not only guarantees product quality but also enhances consumer purchasing interest.

There are special requirements for soda water bottle caps. Since soda water contains carbon dioxide and has a certain pressure, the bottle cap needs to withstand the pressure to prevent gas leakage. Common soda water bottle caps are mostly made of high-strength plastic, and the sealing structure is specially designed, such as the use of multi-layer sealing gaskets.

Some soda water bottle caps also have special devices, such as bottle caps with soda melts, which have a through hole in the middle and are inlaid with soda melts. The upper and lower sides have a protective layer and a waterproof layer that is easy to break. When drinking, the waterproof layer is broken by pressing, and the melt falls into the water to mix soda water, providing convenience for consumers.

In actual applications, we can find many soda can bottle caps. For example, Holyblue Magic Blue Soda Water uses a dark blue aluminum bottle cap with a bright blue phoenix printed on the top of the cap, and two bright blue loops and three small phoenixes on the side of the cap. Its design not only plays a good sealing role, but also adds a unique visual effect to the appearance of the product.

Some imported soda water brands also use aluminum bottle caps. These bottle caps are usually specially surface treated, which not only ensures the sealing, but also improves the beauty and durability of the bottle caps.

As one of the water bottle cap manufacturers, Haomei Aluminum provides various plastic and aluminum bottle caps. Welcome to inquire what you need from us.

Original source: https://www.alubottlecaps.com/a/what-are-requirements-of-water-bottle-caps.html

Previous : Aluminum Bottle Caps for Beer Vodka

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible