Blog

Share this

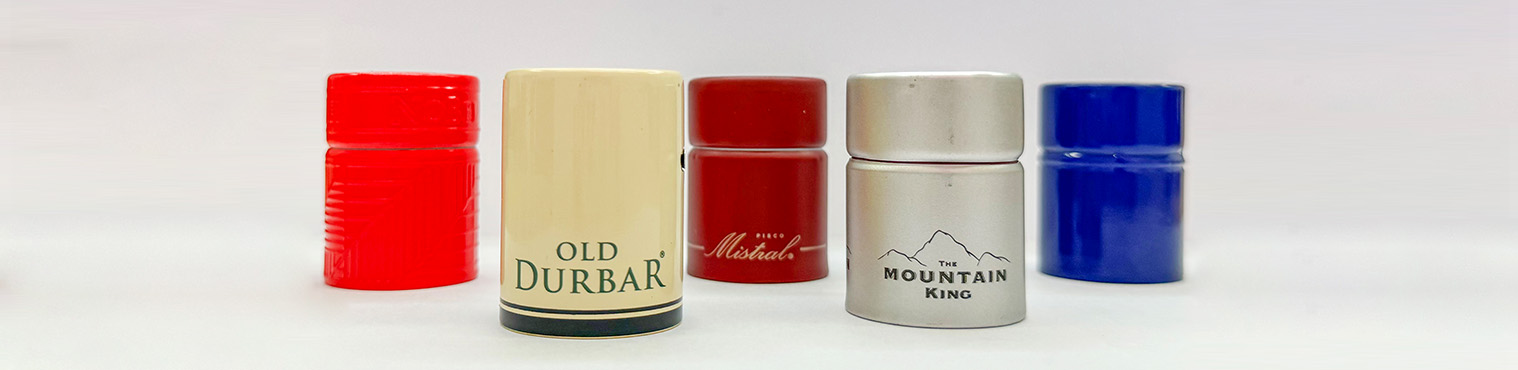

Liquor Bottle Tops VS Beer Bottle Caps

Oct 09, 2025 10:23:37

Whether in a bar or at home, we encounter a variety of bottles every day, but few people notice the differences in bottle caps. While seemingly just "sealing tools," liquor and beer bottle caps differ significantly in material, design, and function due to the distinct characteristics of each type of alcohol. The recent rise in popularity of screw caps for beer has revolutionized traditional bottle caps.

1. Differences in Core Needs

First and foremost, it's important to understand that bottle cap design revolves around the storage needs of alcohol. The alcohol concentration, susceptibility to oxidation, and shelf life requirements of spirits and beer are distinct, leading to fundamental differences in bottle cap design.

Core Needs of Spirits: Long-Term Sealing and Light Protection

The alcohol content of spirits (such as whiskey, brandy, and vodka) is generally above 40% by volume. This high alcohol content inherently has antibacterial properties and provides a more stable body, eliminating the need to worry about spoilage over time. However, spirits typically require long-term storage (ranging from years to decades). Therefore, the core function of liquor bottle tops is to prevent alcohol evaporation and to block out light and dust. Alcohol evaporation reduces the alcohol content, affecting the taste; light (especially ultraviolet light) destroys organic compounds in the beer, giving it a "light flavor" and affecting its quality.

Beer's Core Needs: Oxygen Isolation and Carbonation Retention

Beer's alcohol content typically ranges from 2% to 10% by volume and contains a large amount of carbon dioxide (carbonic acid). Furthermore, components like proteins and yeast in the beer easily react with oxygen, resulting in an "oxidized" flavor (similar to a cardboard flavor) and even spoilage. Therefore, the core function of a beer bottle cap is to completely isolate oxygen (prevent oxidation) and lock in carbonation (prevent the loss of bubbles). Since most beers have a shorter shelf life (a few months to a year), their need for long-term storage is far less than that of spirits.

2. Materials and Design

Based on their different core needs, the material selection and structural design of the two types of bottle caps are tailor-made for each.

Spirits Bottle Caps

The design of spirits bottle caps often balances practicality with a premium feel. Common types include the following:

Metal caps (aluminum/alloy): The most popular choice. For example, whiskey bottle caps are often made of aluminum. The inner wall is fitted with a sealing gasket (usually food-grade silicone or rubber). When tightened, the gasket fits tightly against the bottle opening, creating a double seal that prevents alcohol evaporation while also keeping out air. Some high-end spirits also use alloy caps with engravings for a more premium feel.

Wooden cork + metal cap combination: Commonly used in brandy (such as cognac) or high-end vodka, the wooden cork (mostly oak) is inherently breathable (a small amount of airflow helps the wine age), and the outer layer is covered with a re-openable metal cap. This maintains traditional aging requirements while providing convenience for daily use.

Crystal/glass caps: A decorative option for a very small number of premium spirits, often paired with a silicone gasket. While they still rely on sealant for leak-proofing, crystal caps are more about enhancing the product's perceived luxury.

Based on their differing core needs, the two types of caps are tailored to each other in terms of material selection and structural design.

Beer Caps

Beer caps are designed to offer a quick seal and easy opening, combining tradition with innovation.

Traditional Crown Caps (Press Caps):

The most classic beer cap, made from thin aluminum sheet, feature a corrugated rim (usually 21 teeth, a few 24) and a layer of sealant (earlier asphalt, now mostly food-grade epoxy resin) on the inner wall. They require a bottle opener to pry open, and the seal is a "compression seal"—the cap is pressed onto the raised edge of the bottle mouth by a machine, tightly fitting the corrugated edge. The sealant fills the gap, effectively isolating oxygen and locking in carbonation. However, the crown cap also has significant drawbacks: it's not resealable, and if the beer isn't finished after opening, it can easily leak and spoil.

Beer Screw Caps (Threaded Caps)

In recent years, beer bottle screw caps have gradually become a mainstream choice for craft and imported beers, perfectly addressing the pain points of traditional crown caps. Screw caps are also primarily made of aluminum, with a highly elastic sealing ring (mostly EPDM rubber, which is cold- and alcohol-resistant) on the inner wall, and a corresponding threaded finish on the bottle neck. Their advantages are significant:

Resealable: After unscrewing, they can be re-tightened, temporarily locking in carbonation and air even if the beer isn't finished, extending the beer's drinking time.

No bottle opener required: They can be opened by hand, making them convenient for outdoor use, picnics, and other occasions.

More stable seal: The threaded structure combined with the elastic rubber ring prevents air leaks caused by loose crown caps, making them particularly suitable for high-alcohol, high-carbonate craft beers (such as IPAs and Stouts).

Original source: https://www.alubottlecaps.com/a/liquor-bottle-tops-vs-beer-bottle-caps.html

Previous : What Are Uses of New Plastic Bottle Lids

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible