Blog

Share this

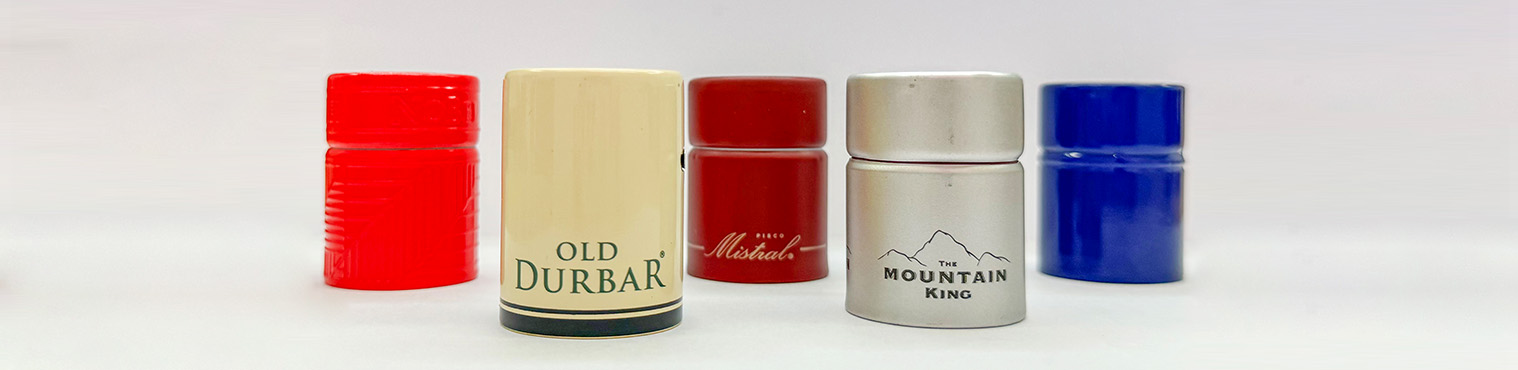

Metal Screw Caps for Glass Bottle

Jan 12, 2026 18:01:48

In daily life, glass bottles are "old friends" that hold all kinds of liquids—from fragrant liquor and rich red wine to refreshing soda and nutritious fruit juice, and even medicinal injections and household soy sauce and vinegar, they are ubiquitous. As the "partner" of the glass bottle, the cap, though inconspicuous, directly determines the liquid's preservation effect, transportation safety, and drinking experience.

Different liquids have different characteristics, and therefore require different caps. First, there are alcoholic beverages. Liquor, red wine, and rice wine, for example, require extremely high sealing performance. Wine bottle screw caps must prevent alcohol evaporation from affecting the taste and also isolate the liquid from air to prevent oxidation and spoilage. Beer, on the other hand, needs additional pressure resistance to withstand the impact of internal carbon dioxide.

Secondly, there are carbonated beverages, such as soda and sparkling water. The high-pressure gas environment requires the cap to have extremely strong leak-proof capabilities. Once the seal fails, the bubbles escape instantly, and the flavor of the beverage is greatly diminished.

Furthermore, food condiments like soy sauce, vinegar, and olive oil are prone to bacterial growth or oxidative rancidity when exposed to air for extended periods. Therefore, bottle caps must not only be airtight but also possess certain anti-contamination and easy-to-open properties.

Medicinal liquids, such as injections and oral liquids, have the most stringent requirements for the hygiene standards, airtightness, and chemical stability of their bottle caps, absolutely preventing any impurities from entering and any leakage of ingredients.

Based on the characteristics of these liquids, glass bottle caps must meet several core requirements:

Firstly, airtightness, which is the most basic and crucial, preventing the intrusion of air, moisture, dust, and other external substances, while also preventing the liquid inside from evaporating or leaking.

Secondly, compatibility, requiring a perfect fit to different sizes of glass bottles. Both the size of the bottle opening and the thread design must be precisely matched to avoid looseness or inability to tighten.

Thirdly, safety, the cap material must not chemically react with the liquid inside the bottle or release harmful substances. Especially for caps that come into contact with food and medicine, they must comply with national food safety or pharmaceutical standards.

Fourthly, ease of operation is crucial. For everyday liquid containers, the cap should be easy for consumers to open and close without the need for special tools.

Fifthly, pressure and corrosion resistance are essential. For liquids with special requirements, such as carbonated beverages and alcoholic beverages, the cap must be able to withstand certain pressure or resist the corrosive effects of the liquid.

Among the various types of glass bottle caps, the application of metal screw caps for glass bottles continues to rise, with aluminum screw caps standing out. According to industry statistics, metal screw caps currently account for over 60% of food and alcoholic beverage glass bottle packaging, while aluminum screw caps account for over 70% of mainstream liquid packaging such as beer, spirits, and juice.

The core advantages of aluminum screw caps in becoming the mainstream glass bottle packaging are concentrated in four points: Firstly, excellent sealing performance; when combined with a sealing gasket, it can form a strong protective barrier, locking in the original flavor of the liquid; secondly, reliable safety; the oxide film properties prevent reaction with the liquid, meeting food and drug standards; thirdly, outstanding cost-effectiveness; abundant raw materials and convenient processing effectively control enterprise costs; and fourthly, practicality and environmental friendliness; the screw design makes it easy to open, and its recyclable properties align with green trends.

Of course, metal screw caps are not the only option. For example, some high-end wines still use corks to highlight their quality, and some condiments use plastic caps to reduce costs. However, from the perspective of the overall market, aluminum screw caps have become the mainstream choice for glass bottle packaging due to their advantages such as good sealing performance, high safety, controllable cost, and environmental friendliness.

Original source: https://www.alubottlecaps.com/a/metal-screw-caps-for-glass-bottle.html

Previous : Why Do Carbonated Beverages Choose Aluminum Bottle Caps

Next : Already the first

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible