Blog

Share this

Why Do Carbonated Beverages Choose Aluminum Bottle Caps

Jan 06, 2026 18:00:30

Unlike regular beverages like mineral water and juice, the core component of carbonated drinks is carbon dioxide dissolved in water. This places far more stringent requirements on the beverage bottle cap than usual.

First and foremost is absolute sealing, the most crucial requirement. Carbon dioxide is a master of escape; even the slightest gap in the cap seal will allow it to leak out, resulting in a diluted taste, loss of bubbles, and the loss of the essence of a carbonated beverage. Experimental data shows that if a regular bottle cap doesn't seal properly, carbonated drinks may lose more than 23% of their gas during transportation. A qualified cap must remain leak-free for one minute under pressure of 0.35 MPa.

Secondly, pressure resistance and deformation resistance are essential. During storage and transportation, changes in ambient temperature cause pressure fluctuations inside the bottle. High temperatures significantly increase pressure, requiring the cap to possess sufficient rigidity and toughness to withstand pressure impacts without deformation or breakage.

Furthermore, the cap must meet safety compatibility requirements: it must be compatible with the efficient operation of automated bottling lines, ensure easy opening for consumers, and have anti-theft features to ensure the product has not been tampered with. Finally, with the increasing popularity of environmental protection concepts, sustainability has become an important consideration, requiring bottle caps to be easily recyclable and reduce environmental burden.

Faced with the stringent requirements for carbonated beverages, aluminum, due to its inherent properties, has become an ideal choice for bottle caps. Aluminium screw caps, building upon this foundation, achieve performance upgrades through structural design, perfectly solving the packaging pain points of carbonated beverages.

Firstly, aluminum itself has excellent barrier properties, effectively blocking the penetration of gases, oxygen, and light. Combined with the special structure of the aluminum screw cap, it achieves double sealing protection.

The aluminum screw cap is formed through a deep-drawing process. The inner surface is usually coated with a clear varnish, forming a tight fit with the plastic gasket at the bottle mouth. The spiral grooves further interlock, ensuring a firm seal between the cap and the bottle mouth, forming a double-sealing structure of "inner stopper + side."

This sealing design not only prevents carbon dioxide leakage but also blocks external oxygen from entering, preventing oxidation and spoilage of the beverage and significantly extending its shelf life. Comparative experiments show that bottled carbonated beverages with aluminum screw caps have an almost zero leakage rate after being inverted for 24 hours, and their gas retention rate is far superior to that of plastic caps.

Secondly, they are pressure-resistant and durable, suitable for complex transportation environments. Aluminum has excellent rigidity and toughness. The aluminum screw caps, processed with special techniques, are made of 8011 or 3105 aluminum alloys.

These alloys possess excellent tensile strength and elongation, capable of withstanding pressure fluctuations caused by temperature changes in carbonated beverages. Even during high-temperature sterilization or long-distance bumpy transportation, they will not deform or break.

In contrast, plastic caps are prone to softening and deformation under high temperatures, resulting in a significant decrease in sealing performance and making them unable to withstand the pressure challenges of carbonated beverages.

Thirdly, they are easy and safe to operate, catering to both production and consumption needs. The screw system of the aluminum screw cap is precisely designed, requiring only partial rotation for easy opening.

The opening torque is controlled within a reasonable range of 1.2~2.5 N·m, making it easy for both adults and children to operate. Furthermore, the anti-theft ring will make a "click" sound when it breaks, clearly indicating that the product has not been opened prematurely, ensuring drinking safety.

On the production side, aluminum bottle caps boast mature processing technology, enabling efficient stamping, stretching, and coating through automated production lines. This meets the large-scale filling needs of carbonated beverages, reducing production losses.

Fourth, they are environmentally friendly and sustainable, aligning with green development trends. Aluminum is an infinitely recyclable material with extremely high recycling rates and low energy consumption during the recycling process. Recycled aluminum can be reprocessed into new bottle caps or other aluminum products without losing its performance.

Data shows that 75% of the world's aluminum is still being recycled. The recycling value of aluminum bottle caps far exceeds that of plastic bottle caps, effectively reducing the environmental pollution caused by packaging waste. Plastic bottle caps, on the other hand, are mostly for single use, have complex recycling and sorting processes, are difficult to degrade, and place a heavy burden on the environment.

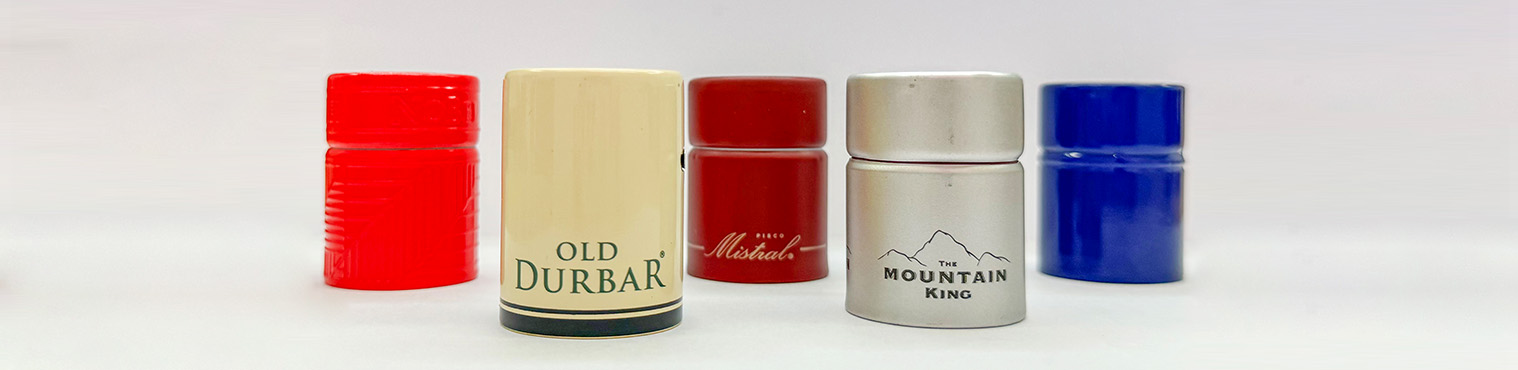

Fifth, they combine aesthetics and practicality, enhancing brand image. Aluminum bottle caps offer a variety of surface treatment processes, including electroplating, painting, and screen printing, allowing for the creation of various exquisite patterns and text. This helps brands differentiate themselves and elevates the overall product image.

For carbonated beverage companies that value their brand image, aluminum screw caps are not only packaging components, but also a vehicle for brand communication, attracting consumer attention in the end market.

Original source: https://www.alubottlecaps.com/a/why-do-carbonated-beverages-choose-aluminum-bottle-caps.html

Previous : Custom Printed Aluminum Caps for Wholesale

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible