Blog

Share this

What Are Sizes of Aluminum Bottle Wine Bottle Caps

Aug 12, 2025 10:30:00

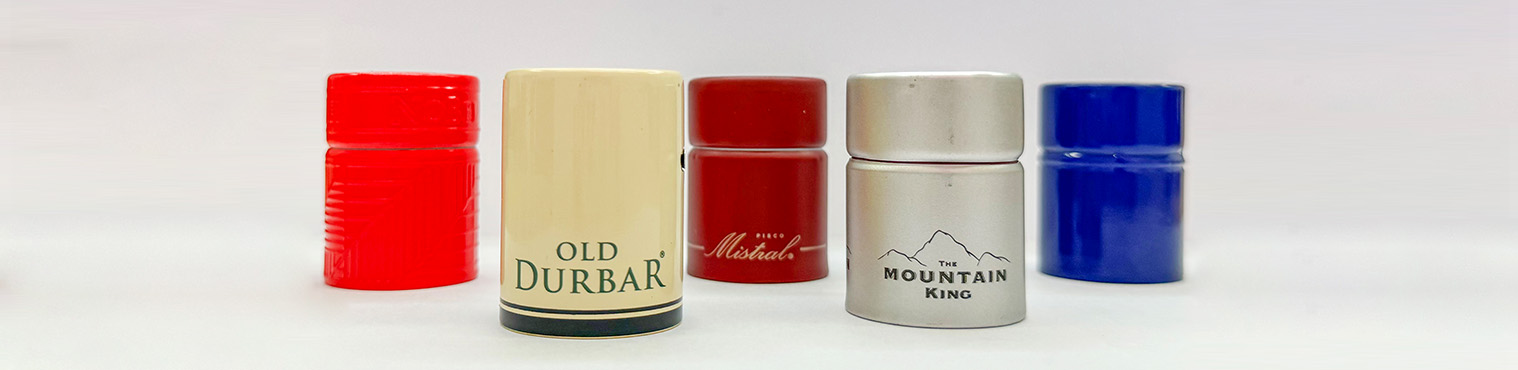

In the world of alcohol packaging, aluminum bottle caps are a favorite of many wine companies for their excellent sealing, corrosion resistance, and aesthetics. The wine bottle cap size is various and different alcoholic beverages often require caps of varying sizes. Common sizes of aluminum bottle caps on the market include the following:

Diameter range 28-30mm: For example, some 500ml bottles of wine might have aluminum caps measuring Φ29.1 x h38.7 and 0.23mm thick. Other common sizes include Φ28.6 x h20.1, 0.21mm thick, and Φ29.7 x h40, 0.22mm thick. For example, the outer caps for some 500ml bottles of authentic aged wines use a Φ29.1 x h38.7 diameter, while a 350ml bottle might use a Φ28.8 x h20.3, 0.21mm thick.

Other special sizes: Other Special Sizes: In addition to the common sizes listed above, some special specifications such as wine bottle caps with diameters between 34 and 36mm and lengths (heights) between 90 and 135mm are also available. Of course, custom sizes can be customized to meet specific production requirements.

Wine companies don't randomly select aluminum bottle cap sizes; instead, they consider a wide range of factors:

Bottle compatibility: The bottle's mouth diameter and height are the primary factors determining cap size. Bottles of varying capacities and shapes have varying mouth sizes. To ensure a perfect fit and a good seal, the cap's diameter and height must be precisely matched to the bottle's specifications.

Large-diameter wine bottles naturally require larger-diameter caps, otherwise they won't seal effectively. Taller bottles may also require a slightly increased cap height to ensure the overall packaging's cohesion and sealability.

Sealing performance requirements: Sealing is the core mission of a bottle cap, crucial to the quality and shelf life of the wine. Thicker cap materials, such as 0.22-0.23mm thick aluminum sheet, often provide better sealing performance and are suitable for high-end wines with extremely high sealing requirements.

Furthermore, the material, size, and fit of the internal gasket within the cap are closely related to the overall sealing effect. The appropriate gasket outer and inner diameters, as well as the thickness of the second bead, ensure that the capped wine is effectively isolated from the outside air, preventing oxidation and deterioration.

Opening convenience: The consumer experience of opening the aluminum caps for bottles should also be considered. If the cap is too large or too small, it can be inconvenient to open. A properly sized cap requires minimal effort, yet avoids spilling the beer due to excessive ease. For example, the height of some beer caps is designed to minimize the amount of effort required to open the bottle.

Production process and cost constraints: Aluminum wine bottle caps are often processed on automated production lines, which place stringent demands on material strength, elongation, and dimensional tolerance. Excessive dimensional deviation can easily lead to cracking or creases during processing, impacting production efficiency and product quality. Furthermore, custom molds may be required for special bottle cap sizes, which undoubtedly increases production costs. Wineries need to balance production process complexity and cost investment while meeting packaging requirements.

Brand image and design style: A unique bottle cap size can become a highlight of brand packaging, echoing the brand image and design style. Some wine companies pursuing individuality and differentiation may choose non-standard aluminum bottle caps, paired with unique printing and craftsmanship, to make their products stand out on the shelf and strengthen brand recognition.

Original source: https://www.alubottlecaps.com/a/what-are-sizes-of-aluminum-bottle-wine-bottle-caps.html

Previous : Cast Aluminium Caps VS Aluminium Seal Caps

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible