Blog

Share this

Why Does Liquor Bottle Screw Caps Prefer Aluminum

Oct 28, 2025 10:37:43

As the first barrier between spirits and the outside world, the choice of liquor bottle screw caps directly impacts the preservation of the liquor's quality, the user experience, and even its brand image. Among numerous materials, aluminum alloy has become a favorite in the spirits industry due to its unique advantages, and its spiral structure is a classic combination.

Why is aluminum alloy so popular among spirit bottle caps?

Unlike lower-alcohol beverages like wine and beer, spirits generally have an alcohol content (ABV) above 40% by volume, with some reaching as high as 60%. High alcohol concentrations are highly volatile and corrosive, placing extremely high demands on the sealing and stability of bottle caps. Aluminum alloy caps precisely meet these requirements, making them the industry's leading choice. This is due to three key advantages:

1. Sealing

High-alcohol spirits require a sealing performance far greater than that of standard beverages. If the seal fails, alcohol will continue to evaporate, resulting in a weaker taste and unbalanced flavor. Furthermore, oxygen and moisture from the air will enter the bottle, triggering oxidation reactions and producing off-flavors.

Aluminum alloy has excellent ductility, allowing it to conform tightly to the curvature of the bottle mouth during processing, creating a seamless seal that effectively blocks alcohol evaporation and prevents the ingress of impurities.

Compared to traditional corks (which are susceptible to deformation due to temperature and humidity, and can develop a corked odor) and plastic caps (which can chemically migrate with alcohol over time), aluminum alloy offers greater chemical stability and resists reaction with alcohol, ultimately safeguarding the purity of the spirit.

2. Safety

For spirits intended for direct consumption, the contact between the bottle cap and the spirit must meet strict food-grade safety standards. High-quality aluminum alloy caps are made from food-grade aluminum and undergo surface treatments such as anodizing and spray coating to create a dense oxide film that prevents metal ion migration and resists minor corrosion from alcohol.

Furthermore, the production process for aluminum alloy caps can be fully automated, reducing the risk of contamination from manual contact—a crucial feature for spirits brands focused on quality control.

3. Practicality and Aesthetics

From a practical perspective, aluminum alloy is lightweight yet durable, easy to process, and can be easily adapted into a variety of structural designs (such as spiral and push-type caps). It also offers convenient opening. Compared to bottle caps that require a corkscrew, spiral aluminum alloy caps better meet consumers' demand for convenience.

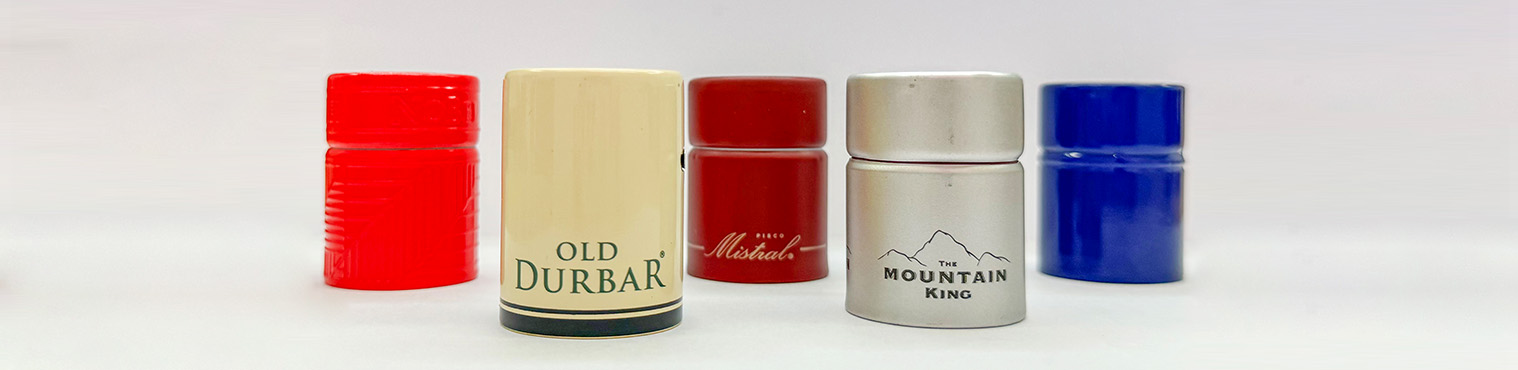

From an aesthetic perspective, aluminum alloy surfaces can be treated with processes such as electroplating, silk screen printing, and laser engraving. These processes can imprint brand logos, alcohol content, and other information, while also enhancing the product's premium quality through a metallic sheen. For spirits like vodka, which prioritize purity and simplicity, silver or matte aluminum alloy caps visually complement the transparent bottle and pure spirit, reinforcing the brand image.

4. Screw Structure

The screw structure dominates the structural design of spirits bottle caps, becoming a near-standard feature, particularly for mainstream spirits like vodka and whiskey. The core reason this structure is so popular is that it perfectly strikes a balance between "sealing" and "convenience." Vodka's preference for the spiral structure is deeply tied to its product characteristics.

The Core Advantages of the Screw Structure

The screw structure works by precisely interlocking the inner threads of the cap with the outer threads of the bottle neck, creating a "physical lock." When tightened, the sealing gasket (usually made of food-grade silicone or EVA) at the bottom of the cap is compressed, fitting tightly against the bottle neck, further enhancing the seal.

The advantages of this structure are: Firstly, the threaded engagement creates a stable seal, unaffected by external factors like temperature and transport vibrations, preserving the quality of the liquor over time.

Secondly, consumers can simply tighten and loosen the cap clockwise and counterclockwise without the need for tools, making it convenient and particularly suitable for frequent openings at home or in bars. In contrast, push-type and snap-on designs, while convenient to open, are prone to problems like aging of the sealant and loosening of the sealant over time, leading to a rapid loss of sealing performance.

Cork stoppers with metal caps, while offering a premium feel, are difficult to open and require stringent storage conditions, making them unsuitable for spirits like vodka that require long-term storage and frequent opening.

Vodka's Preference for Screw Bottle Caps

Vodka's core characteristics are its high alcohol content (typically 40% vol) and purity, which require an exceptionally tight seal. If the seal fails, alcohol evaporation will directly diminish the flavor, while impurities can intrude, compromising the spirit's "pure" core flavor.

The screw-on aluminum alloy cap's dual-seal design of "thread + seal" minimizes alcohol evaporation, ensuring consumers enjoy the original, pure flavor of the spirit every time they open it. In addition, the application scenarios of vodka consumption also determine the adaptability of the screw cap: whether it's repeatedly opened at family gatherings or frequently used for cocktail mixing at a bar, the convenience of a screw cap enhances the user experience.

It's worth noting that some high-end vodka brands have even upgraded their vodka bottle caps. For example, Sweden's Absolut Vodka uses a one-piece aluminum alloy screw cap with a matte finish and a simple brand logo, maintaining a tight seal while reinforcing the brand's minimalist aesthetic. Meanwhile, Russia's Smirnoff Vodka incorporates a leak-proof rubber gasket inside the cap, preventing leaks even when the bottle is inverted, further optimizing transportation and storage.

Original source: https://www.alubottlecaps.com/a/why-does-liquor-bottle-screw-caps-prefer-aluminum.html

Previous : What Are Features of The Cap QR Code

Share this

- Email: sale@alubottlecaps.com

- Tel: +86-15978414719

- Address: CBD, Zhengzhou, Henan, China

Inquiry

We will reply to you as soon as possible